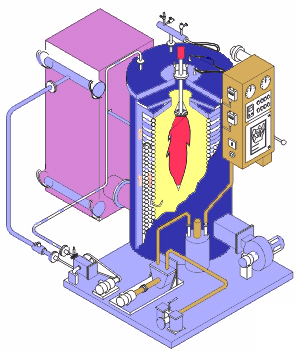

Smoke Tube Boiler

- Capacities from 400 kg/HR. to 20,000 kg/HR. for oil/ gas fired. From 400 kg/HR. to 3,000 kg/HR. for coal fired.

- Package boilers of three pass, smoke tube type in completely wet back construction without any refractory at the rear.

- Designed to meet present day demand of high efficiency, easy maintenance, simple installation and low running cost.

- The automatic and semi automatic control.

- Compact design requiring less space.

- Easy access for cleaning of smoke tubes.

- Low cost of civil foundation and installation.

TYPES:-

1) OIL FIRED BOILERS:

2) SOLID FUEL BOILERS:

TWIN FURNACE COAL FIRED BOILER:- COAL FIRED BOILER:-

3) SMALL BOILERS:

- The boiler shell made from boiler quality steel, with insulated body is made from quality tubes of STANDARD 3059/I as per BSS standard. And it is fully automatic producing steam within 3 minutes of cold start. and economizer for high efficiency.

- A high pressure atomizing JET BURNER ,a self cleaning oil filters, high pressure oil pump fuel oil per heater, blower with adjustable air regulator & spray nozzle for firing system. The package unit consist with firing system, water tank, softener plant, steam separator for dry steam.

- The centralized control panel fitted with instruments and with with audio & visual alarm for flame failure, high temp. of steam, low level in water tank, overload of blower overload of B.F.P. This adds to the simplicity and safeties The boiler does not require any foundation & comes as one unit & requires less space.

- Our boiler can run on H.S.D./KEROSENE/L.D.O./F.O. (Furnace oil).

- Asian package is fully automatic and easy to operate and there is no necessary of operator, in Super Steam Boiler oil consumption is very less and operating cost is very low.

- Can be converted in to Hot Water Boiler.